How to pick the right printing technology?

Clothing & bags decoration technologies

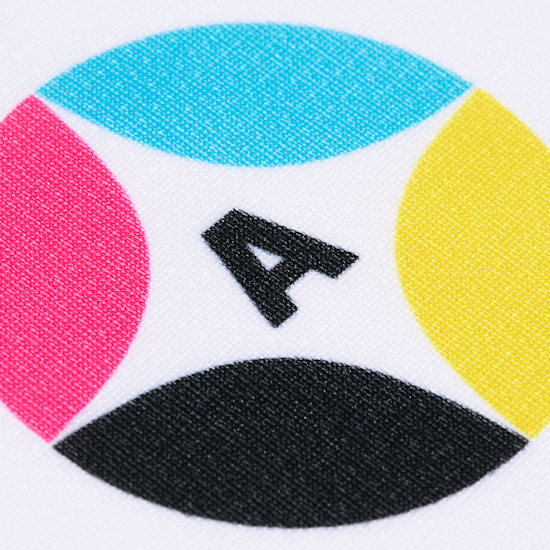

Durable, best value in bulk. Not recommended for photos, fine details or multiple-colored logos.

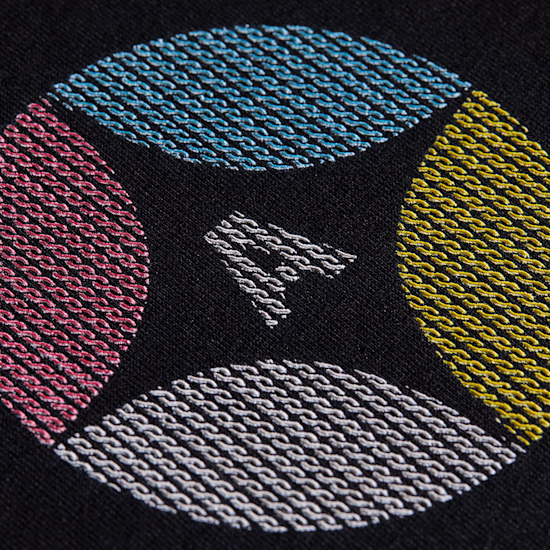

Long-lasting, premium look with 3D effect. Unavailable for use with white fabrics.

Ideas & Advice

Make your logo stand out with VistaPrint printing technologies.

Choosing the right decoration technology for your brand can make all the difference in how your products look, feel and connect with customers. Each method brings its own unique qualities to your design. So, if you're creating uniforms, Screen Printing is your go-to choice - great value in bulk and the print lasts wash after wash. For a classic, professional touch, Embroidery adds texture and depth that gives your logo a professional look you’ll love. If you want something bold that really stands out (literally), Textured Direct-to-Garment offers a raised 3D effect that’s as eye-catching as it is durable. And for an elegant touch on promotional items, laser engraving adds a refined finish that impresses.

Finding the right decoration technology to match your brand’s style and needs not only enhances the appeal of each product but also reinforces a strong, memorable brand image. Not sure where to start? No worries. Our experts are here to help guide you to the right decoration technique that meets your needs.

Made by you, #MadeWithVistaPrint

Frequently asked questions

Your unique touches can be added to custom clothing and bags using different decoration techniques, including:

- Screen Printing: 1 print color for a smooth, slightly raised feel.

- Direct-to-Garment: unlimited print colors & designs for a soft hand feel.

- Textured Direct-to-Garment: unlimited print colors and designs, raised & tactile feel, offers a 3D effect.

- Heat Transfer: unlimited print colors for a firm, plastic-like feel.

- Dye Sublimation: unlimited print colors for a vibrant, permanent print.

- Embroidery: up to 12 thread colors for a textured, professional look.

Choosing between Embroidery and Textured Direct-to-Garment depends on the look and feel you want for your logo or design.

Embroidery is a classic choice that adds a textured, professional feel-ideal for a more traditional look.

It's highly durable and works especially well on fabrics, like hats, jackets and uniforms. If you're aiming for a polished, professional appearance, embroidery is a great option.

Textured Direct-to-Garment, on the other hand, creates a raised, 3D effect that really makes your design pop. It's bold, modern and eye-catching- giving a unique tactile experience. Textured Direct-to-Garment is durable as well and can be a great choice if you want your logo to have that extra dimension.

There are several printing technologies used for clothing and bags, each with its own method:

- Screen Printing: a thick layer of ink is pushed through a mesh screen onto your garment.

- Direct-to-Garment: ink is sprayed onto your garment and absorbed into the fibers.

- Heat Transfer: your design is printed onto vinyl film and heated onto the fabric.

- Embroidery: your design is stitched onto the fabric with colored threads.

- Dye Sublimation: heated ink absorbs into your garment.

- Textured Direct-to-Garment: your design is printed in layers, creating raised 3D effects without threads.

- Pad Printing: ink is stamped onto the surface of your product.

- Dye Sublimation: heated ink transforms into gas and fuses directly into the material.

- Digital Inkjet: ink is printed directly onto the surface of your product.

- Laser Engraving: your design is etched onto the surface of your product.

For small hard goods like pens, pad printing offers a smooth, durable finish, while laser engraving provides a sharp, permanent look. Both methods ensure your design stays crisp and professional.